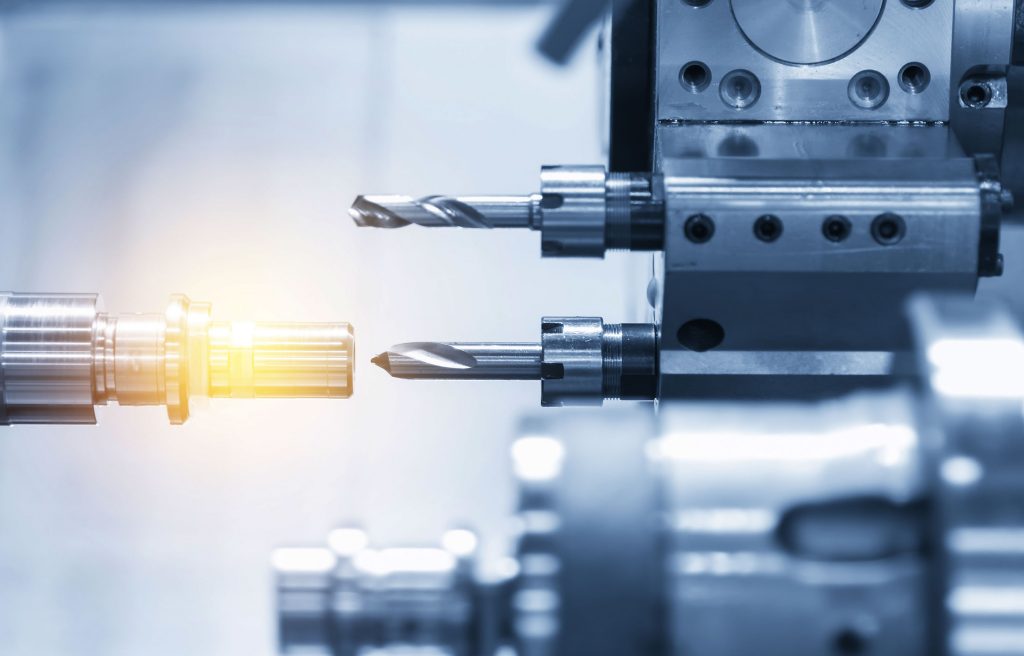

Simultaneous machining

Solid and reliable

Up to 30% cycle times

Customer service

Machines

Projects

Technologies

and Solutions

Research, experience, deep skills of understanding customer’s needs characterize all IVAXIA projects

Advices

pre-sale

Support

and Advices

IVAXIA’s customer care service guarantees a reliable service during and after the purchase thanks to its high qualified staff

Products

Centering Machines

Centering

Machines

All changes and improvements of IVAXIA’s equipments are the result of a continuous technological evolution

Assistance

After-Sale

Assistance

and Support

IVAXIA’s Customer Service guarantees an after sale support completely oriented to the customer satisfaction

Our products

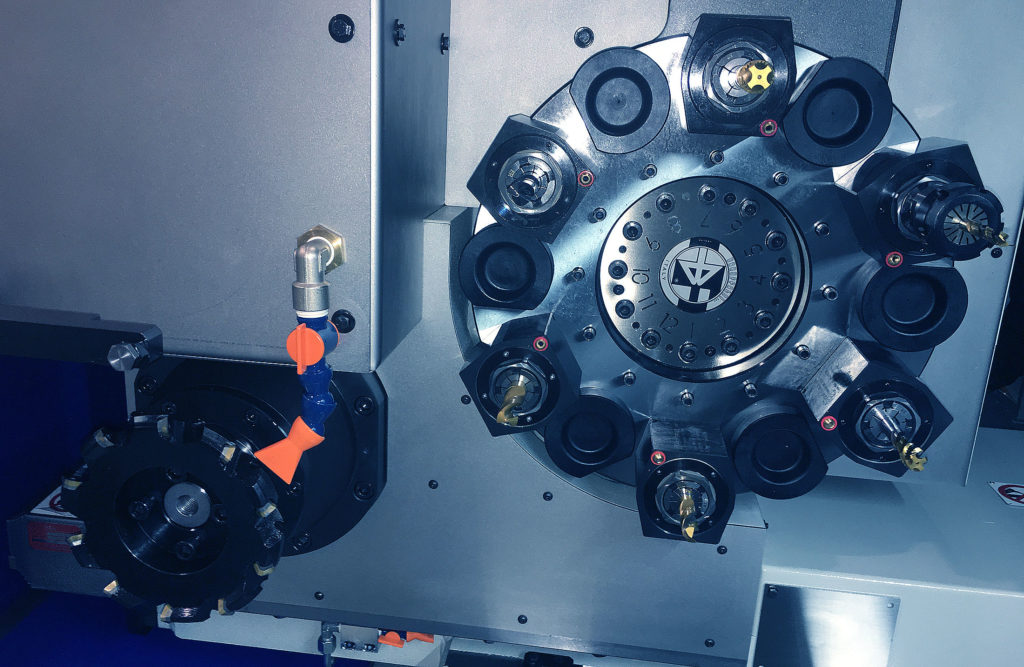

CENTERING MACHINES

Technologies and solutions for ends working

CF Series

Our models for tubes, pipes, hydraulic cylinders and roller conveyors elements

MM Series

Universal models for working pieces with huge diameters (diam. 30-300 mm)

MF Series

Universal models for working pieces with average diameters (diam. 20-180 mm)

MG Series

Our model dedicated to pieces having small dimensions (Ø max. 80mm and length max. 600 mm)

FLEX Series

A model for offering the working maximum flexibility using standard tools only for pieces with averages diameters

FLEX-Y Series

Having all good features of previous FLEX Series but with each working head endowed with an additional “Y” axis allowing off-axis drillings (max. +/- 125 mm)

OMNI Series

Also equipped with the "Y" axis, it is a model designed to solve any production problem on the ends of large pieces with a diameter of up to 400 mm

Who we are

Ivaxia srl

Born with the intention of adding a new line of even more flexible machines to our production branded COMINI offering

the possibility to work even on the “Y” axis keeping unchanged the features that still characterize our machines today:

Our services

Our commercial technicians follow the negotiation step by step to support the customer in choosing the model most inclined to his needs with the possibility of making customizations. Our service network is available both remotely and on site with highly qualified mechanical, electrical and software engineers.